Recently, SMG Global shared an informative post detailing the various testing methods used during custom PCB manufacturing and assembly, primarily focusing on fly-probe testing and in-circuit testing. In addition to these tests, however, custom PCB design also uses a number of verification tools to ensure quality. We delve into the nature of these PCB inspection tools below. From solderability tests to PCB contamination inspections, discover these PCB tools’ integral roles in SMG’s impressively low product return rates.

PCB Inspection and Analyzing Tools: Solderability Test

One of the most helpful PCB inspection and analyzing tools is the solderability test. This tool helps to ensure that the custom PCB designs demonstrate acceptable surface sturdiness according to J-STD-003. The use of this tool improves each PCB’s chances of forming a dependable solder joint. Related solderability tools can also be used to determine the level of thermal stress that a PCB’s holes can withstand.

PCB Inspection and Analyzing Tools: PCB Contamination Testing

PCB contamination testing, which verifies custom PCB projects by detecting ionic material that may cause board corrosion further down the road, is an analyzing process that is actually composed of several PCB inspection tools, such as Fourier Transform Infrared (FTIR) Spectroscopy, Ion Chromatography (IC), and Surface Insulation Resistance (SIR).

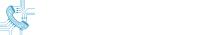

PCB Inspection and Analyzing Tools: Micro-Sectioning Analysis

Printed circuit boards are rarely composed of just one uniform material type. Instead, these assemblies often involve a combination of copper, acrylic, glass, and more. Because these materials possess different hardness profiles, micro sectioning is used to determine the overall quality of these materials working together within a circuit board. A competent operator utilizes this tool to locate defects, opens, shorts, and design failures.

PCB Inspection and Analyzing Tools: Peel Test

Peel tests are used to determine the amount of force required to peel the laminate from the board. This PCB tool is a type of destructive inspection, meaning around three to five individual PCB boards are used to measure each test point, becoming unusable after the process is completed. This level of ruination is incomparable to the amount of waste that is prevented through the peel test process.

PCB Inspection and Analyzing Tools: X-Ray Tools

X-Rays prove to be handy PCB inspection and analyzing tools. This equipment offers a non-destructive way to verify SMT processes of PCB assembly and provides high-definition imaging for locating defects within PCB assemblies. Additionally, X-Ray fluorescence & capacitance plating thickness is vital to SMG Global’s custom PCB design and manufacturing process.

Comprehensive Selection of PCB Inspection and Analyzing Tools for High-Quality Results

As you can see, several tools are involved in the custom PCB design and manufacturing process. By using the leading inspection and verification tools available, SMG Global delivers PCB orders that meet every quality standard the industry has to offer. Discover the quality of our PCB inspection and analyzing tools for yourself by placing your next custom PCB order with our all-star team!