PCB Blind & Buried Via

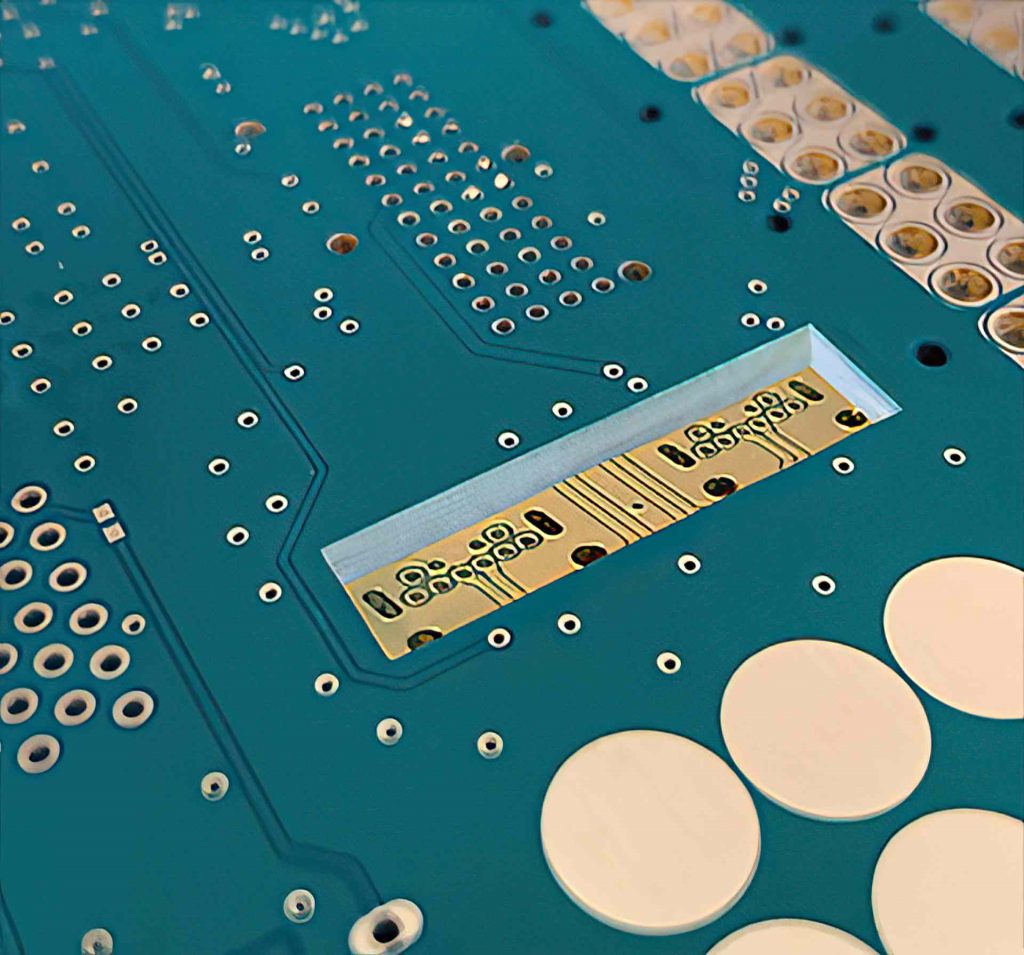

The blind and buried vias manufacturing techniques provide many advantages, especially in regards to saving space. SMG can expertly fabricate PCBs using either method, ensuring a finished product that is tailor-made for your needs.

How Blind Vias Are Implemented in PCB

How Blind Vias Are Implemented in PCB

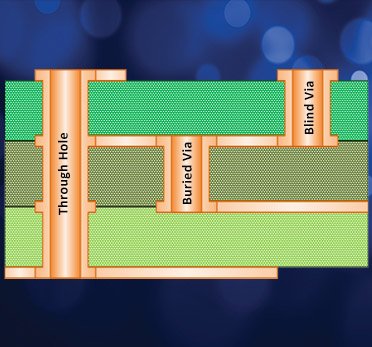

Blind vias are the solution when PCB space is compact, or you require tight through-hole constraints. A blind via connects one outer layer to one or more inner layers. In simple terms, we drill and plate depth-controlled holes which do not go through the entire PCB.

How Buried Vias Are Implemented in PCB

The buried vias design technique also saves space when a compact design is needed for your PCB. Within high-density boards, buried vias connect inner layers without going through the entire board. When working with this technique, the buried vias are not visible from the outer layers.

Competitive PCB Blind and Buried Via Pricing

SMG Global is proud to price all of our PCB products and services competitively. While other companies may put a high price on blind or buried services due to complexity, SMG specializes in challenging projects, so we are usually able to offer better prices than the competition.

Alternatively, if you are looking for another way to work with compact PCB design, consider utilizing our via in pad service. This option connects PCB traces across multiple layers.

Accredited Blind and Buried Via Service for PCB

Accredited Blind and Buried Via Service for PCB

SMG Global Circuits, Inc. has been manufacturing top-quality printed circuit boards (PCB) for various markets since 1989 and providing blind and buried vias in PCB for just as long! We have kept up with the latest ISO 9001 certifications since 1996, and we are also ITAR registered.

Satisfying Customer PCB Needs With Via In Pad Service

SMG Global has developed excellent customer relationships and satisfaction with our 99%+ on-time delivery record for products that involve blind/buried vias, as well as other advanced PCB techniques. Our primary goal is to maintain a robust quality system that emphasizes defect prevention and reduction of waste in the supply chain. We accomplish this through Quality Assurance System Goals, Quality Circles, Internal Quality Audits and a Calibration and Preventive Maintenance program for all of our equipment. With SMG Global, you will never have to worry about blind or buried via quality issues — We have you covered!

How Blind Vias Are Implemented in PCB

How Blind Vias Are Implemented in PCB Accredited Blind and Buried Via Service for PCB

Accredited Blind and Buried Via Service for PCB