In the world of PCB manufacturing, one will encounter many manufacturers who talk about their PCB inspection and testing capabilities, but customers who are new to the industry may have trouble finding information that explains the distinction between the two techniques.

While it is true that both PCB inspection and testing serve a similar purpose in ensuring the final product meets high quality standards, these capabilities differ from each other in key ways. A PCB manufacturing company worth trusting must be a company that understands these crucial differences and employs an expert workforce to carry out both manufacturing techniques. Explore an overview of both PCB inspection techniques to become better informed before placing an order:

PCB Inspection

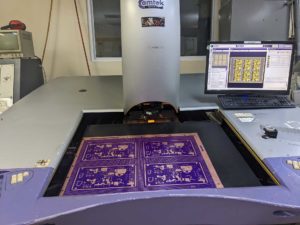

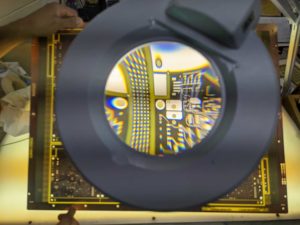

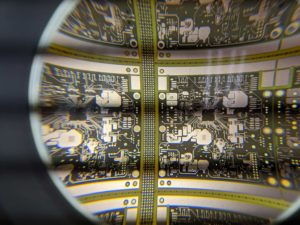

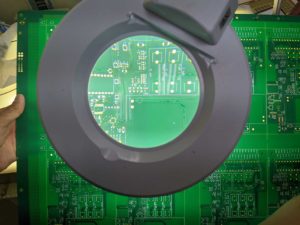

Visual and automated PCB inspections are implemented during many stages of the production process. Inspections are implemented to spot defects earlier on in the manufacturing process to ensure pcb’s meet our quality standards.

Why Bother with PCB Inspection?

If a PCB board is scheduled to receive final PCB testing, it may seem redundant to implement a number of PCB inspections as well, but these inspections are in fact quite integral to the overall efficiency of PCB manufacturing. While it is true that final tests verify the functionality of the PCB manufacturing, inspections are the key to spotting product defects before they cause functionality issues and any delays.

By employing PCB inspections early and often during the PCB manufacturing process, it is possible to catch defects earlier on during manufacturing. Because these inspections catch errors as they happen, it not only becomes easier to fix any particular problem areas during the manufacturing process, it also ultimately reduces the production costs and eliminates a great deal of waste. So while thorough PCB inspection may seem slightly time consuming, these quality assurance techniques are the key to quick and cost-effective final products.

The Results of Comprehensive PCB Inspection

As you can see, both PCB inspection is important to the manufacturing process for circuit boards. SMG is proud to guarantee high quality final products thanks to our commitment to equipping ourselves with cutting edge equipment and a well-trained workforce. Because each PCB project requires specific methods of inspection and testing processes based upon its unique design and functionality, it is useful to understand the full extent of your PCB production partners testing and inspection capabilities, which is why SMG has a more detailed overview of these services in our previous blog posts. We invite you to explore our services for yourself and discover how our company has delivered excellence for over 30 years!