Electroplating, which is sometimes referred to as electrodeposition,is a crucial element of the PCB manufacturing process. Electroplating works by depositing a metallic coating to allow for an electrical signal to be distributed along the printed circuit board, but it is important to note that there are multiple different methods that can be employed to achieve the desired electroplating effect.

The four main types of electroplating include finger plating, through-hole plating, reel selective electroplating, and brush plating. Explore these electroplating options more fully by reading further:

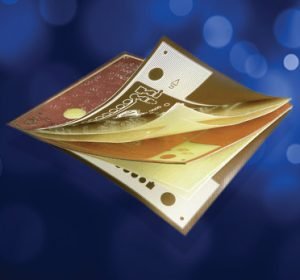

Gold Tab Electroplating

Gold Tab plating is one of the most common electroplating methods in the PCB manufacturing industry. This method works by depositing a hard gold plating onto the surface of printed circuit boards. This gold alloy consists of both gold and nickel, as nickel increases the hardness and general wear resistance of the deposited coating, while the gold material ensures that the nickel is protected from oxidation.

Gold tab elements are advantageous to PCB design as this method of electroplating provides a great deal of flexibility. Gold tab plating can be implemented as uniform pads, each having the same length, width, and space, or they can be designed to have uneven lengths or even segmented features.

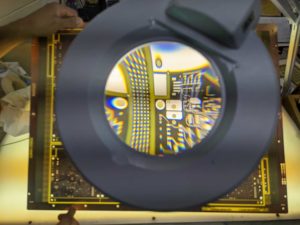

Through-hole Electroplating

Another electroplating process commonly used by PCB manufacturers is through-hole electroplating. Like finger plating, an alloy of gold and nickel can be used to withstand oxidation. The difference of through-hole plating is that this method of electroplating is solely used for plating components that run through the board, as opposed to surface mounted components. By plating through-holes, manufacturers ensure their components will better withstand the environmental stress that the printed circuit boards will be exposed to.

Invest in Expert Electroplating with SMG Global

As you can see, there are options to choose from when electroplating your printed circuit boards. Because each method has its own advantages and unique uses, many customers appreciate SMG’s commitment to customer service, as we ensure that every client is properly informed of the electroplating strategies that will best suit their PCB design. For more information regarding this important element of PCB manufacturing or other design elements, contact our team of experts today!