Your Project, Our Priority

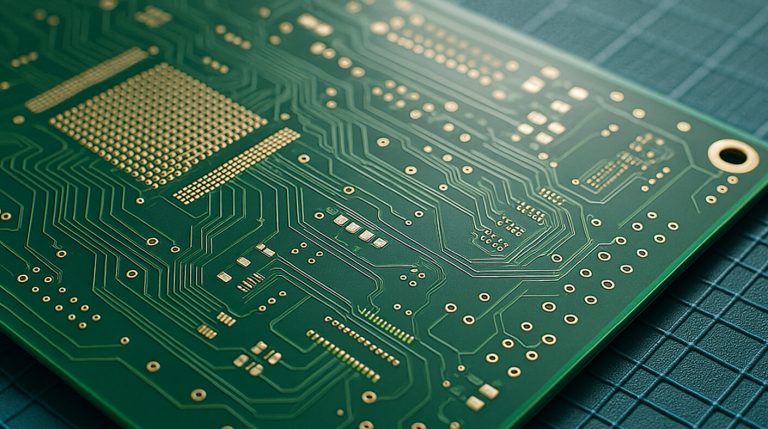

Full-Spectrum PCB Manufacturing Services

At SMG-Global Circuits, we offer integrated solutions designed to support your product lifecycle at every stage. Our services are built upon a foundation of technical precision, flexibility, and speed, ensuring we can meet the unique demands of both cutting-edge prototypes and complex mass production runs.

services

-

Aluminum Boards for LED Applications

The core concept of aluminum boards is to dissipate heat from the circuit area…. Read More

-

Impedance Control

SMG Global Circuits covers all of our bases when it comes to excellence in PCB…. Read More

-

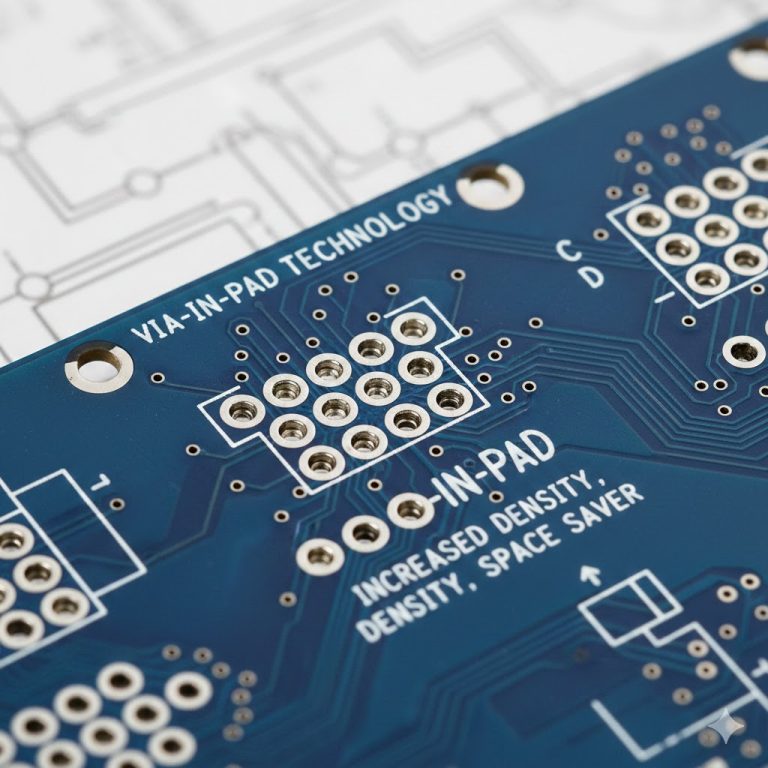

Via in Pad

Via in pad is the plated through hole in the pad to link PCB trace from one layer… Read More

-

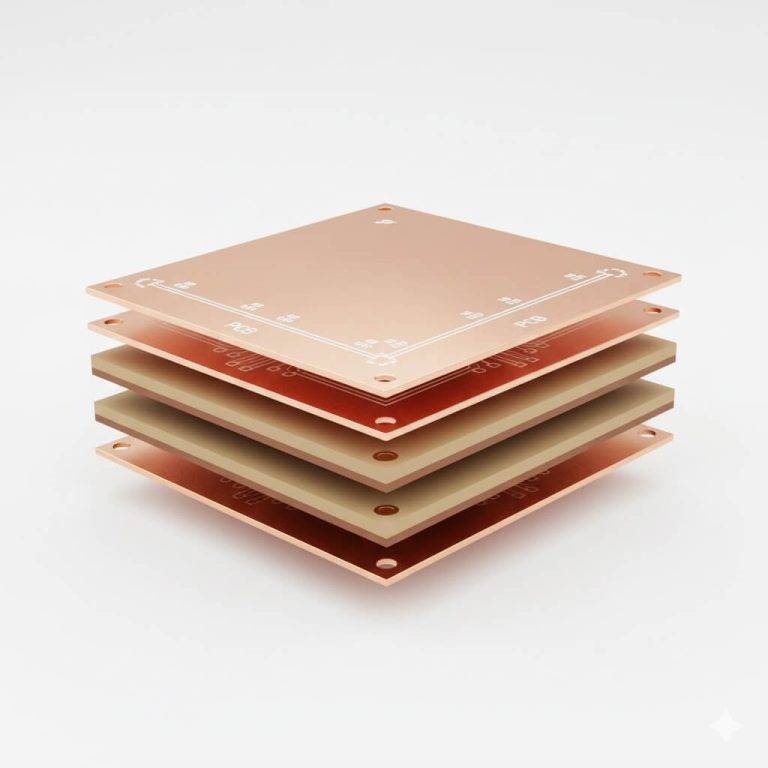

Multilayer Board

Multilayer circuit boards are boards that contain more than one conductive inner… Read More

-

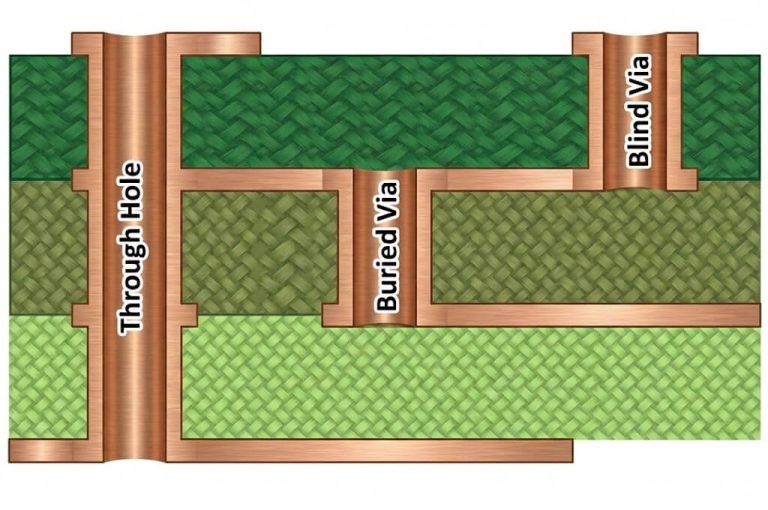

Blind/Buried Via

The blind and buried vias manufacturing techniques provide many advantages… Read More

-

PCB Finishing Processes

SMG Global uses PCB finishing processes to protect exposed copper circuitry….. Read More

-

PCB Edge Plating

Edge plating is a technique of PCB manufacturing where the top and bottom side…. Read More

-

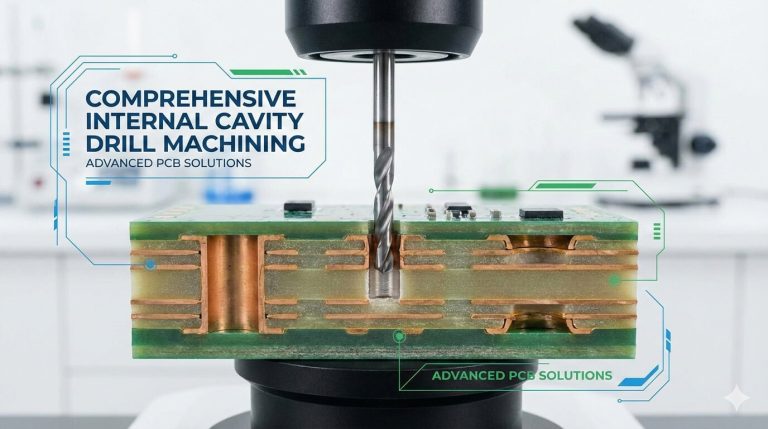

Internal Cavity Drilling

Internal cavity drilling is an increasingly popular solution for PCB requirements…. Read More

Rapid Prototype

PCB Manufacturing

We believe that every space has the power to inspire, and that great design brings that inspiration to life. Our mission is to craft environments that stir creativity, evoke emotion, and reflect the essence of those who inhabit them.

Quick-Turn

Excellence

Focused on speed to market, delivering fully functional prototypes in minimal lead time.

Rigorous

Testing

Prototypes undergo the same strict quality control as production units, ensuring design validation and reliability.

Design

Optimization

Our engineering team provides crucial Design for Manufacturability feedback to optimize your design before scaling.

High-Volume Production PCB Manufacturing

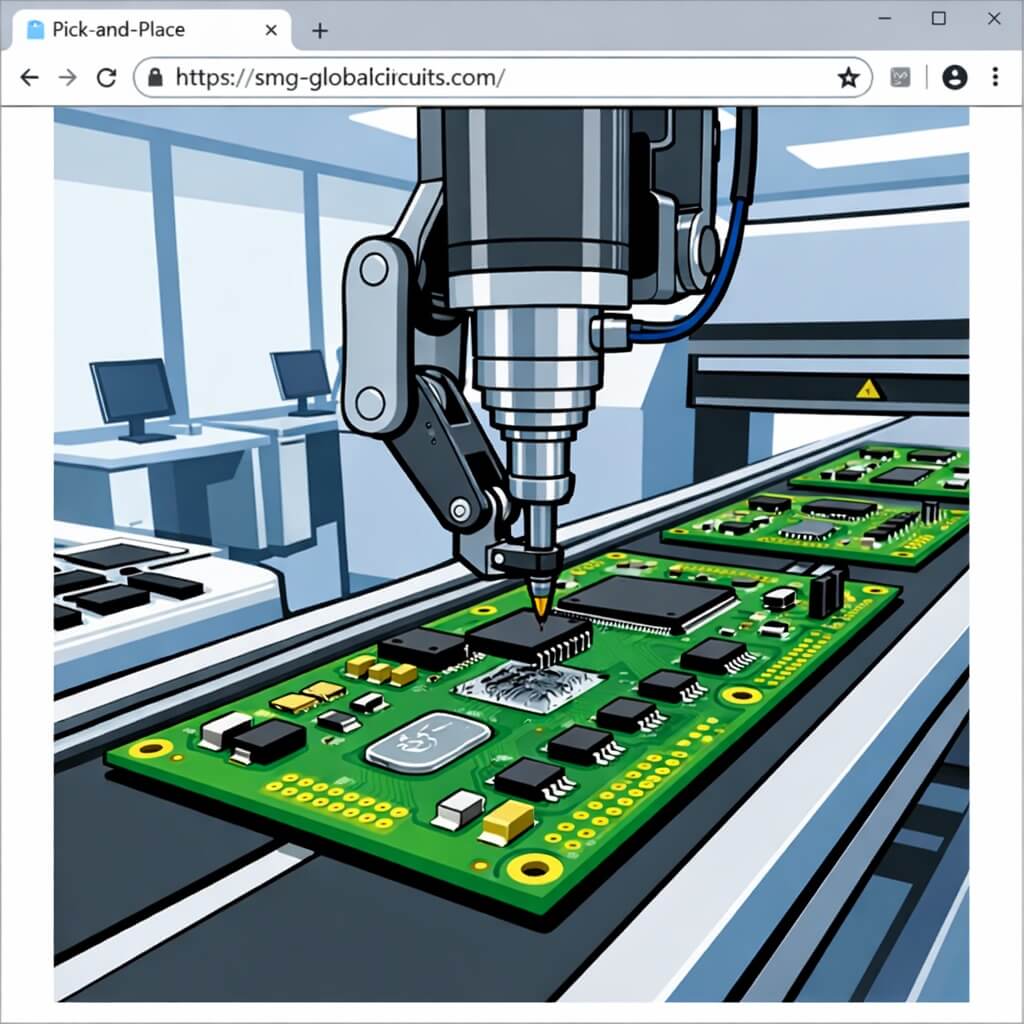

Scalable Capacity

Robust manufacturing facilities capable of efficiently handling large-scale, high-volume orders.

Cost Efficiency

Optimized production processes and a global supply chain drive competitive pricing for large orders.

Repeatable Quality

Utilizing automated manufacturing and inspection systems to guarantee consistency and zero defects across millions of units.

- Quick Value-Added Services

Mission-Critical Quick-Turn Solutions

When your project cannot wait, our dedicated Quick-Turn service provides an accelerated path for both prototyping and small-batch production. We prioritize your urgent timelines while maintaining all of our rigorous quality and inspection standards. Contact us immediately to initiate a fast-track order.

Comprehensive Value-Added Services

Material Selection Consulting

Guidance on choosing specialized substrates (e.g., rigid-flex, high-frequency) for challenging applications.

Technical Support & Design Review

Access to our expert engineering staff for detailed design checks and technical consultation.

Advanced Surface Finishes

Expertise in specialized finishes, including Immersion Tin and OSP.